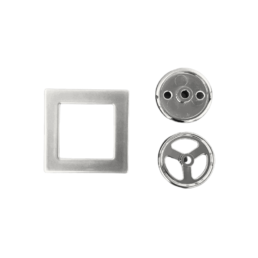

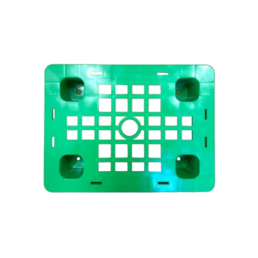

We help you produce any plastic part to meet your expectations

Welcome to the IPIC Plastic website, your trusted partner for Plastic Injection in Belgium. We have been manufacturing plastic parts for over 30 years. Our unmatched expertise in plastic injection allows us to provide sustainable and high-quality solutions to a wide range of industrial sectors.

Our Reputation: Excellence in Plastic Injection

As a leading plastic injection company, IPIC Plastic has built a reputation for excellence in producing plastic parts. Our expertise, dedication, and experience make us the ideal choice for all your injection molding requirements.

Our Commitment: Custom Plastic Parts

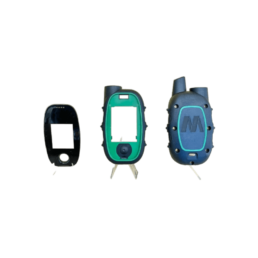

Our plastic injection process is both precise and efficient, ensuring that each part we manufacture meets your expectations. We understand that every customer has unique needs, and we strive to provide customized plastic injection solutions that precisely address those needs.

Our Vision: Innovation at the Core of Our Business

At IPIC Plastic, we are more than just a plastic parts manufacturer. We are innovators, constantly seeking ways to improve our plastic injection processes and deliver the highest quality products to our customers.

Our Expertise: Injection Molding

Injection molding lies at the heart of what we do. This complex technique involves injecting molten plastic into a mold to create parts with specific shapes, requiring precision and technical know-how. Thanks to our many years of experience, we have perfected the art of injection molding, ensuring high-quality parts every time.

IPIC Plastic: A Reliable Plastic Injection Company

IPIC Plastic is a plastic injection company you can rely on. Our technical expertise, combined with our commitment to customer service, makes us the ideal choice for all your plastic parts requirements.

Discover IPIC Plastic

We invite you to explore why IPIC Plastic is recognized as a leader in the plastic injection industry. Browse our website to learn more about our injection molding services, plastic parts manufacturing processes, and how we can help your business succeed. We look forward to working with you to create durable and high-quality plastic injection solutions.

Why IPIC plastic?

IPIC Plastic has been a specialist in plastic injection molding for over 30 years

Expert advice

Injection molding is a complex manufacturing process that requires specialized knowledge and experience. This is why you can rely on our experience, expertise and in-depth knowledge of materials, tooling, and production processes to assist you in designing and producing high-quality products the way you intend it to be.

Cost-effective

At IPIC PLASTIC, our goal is to provide more value to you as a customer by delivering faster production cycles, improved product quality, and more cost-effective manufacturing solutions. We do this by investing in advanced technologies and equipments ensure efficient and precise production processes.

Customized and flexible

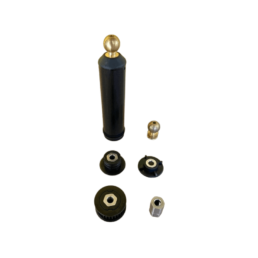

Injection molding is known for its versatility, allowing for a wide range of product designs and sizes. At IPIC PLASTIC, our goal is to offer options to meet your unique needs. This can include customization of product design, material selection, color options, finishes, and other custom specifications.

30

Years of experience

10M

Parts made annually

12

Sectors served

13

Countries worldwide

900

Designs produced

How we can help?

From full-solution to any specific support you need

Post-production

Worry-free service where your plastic parts are assembled together. Eg: placements of inserts, ultrasonic welding, assembly of several parts, labelling, overmolding.

Quality Guarantee

We guarantee the quality of your plastic piece through stringent internal quality check processes.

Transforming ideas into reality

Technologies

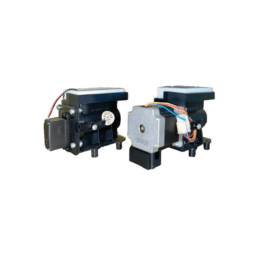

Unlock a multitude of possibilities with our versatile tooling park

Machine park of >10 injection presses ranging from 22T up to 300T.

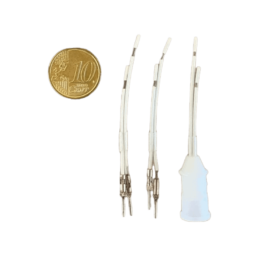

Able to perform micro-injections as of 0.1 cm3 up to pieces of 800 cm3 in volume

Your plastic piece with your choice of material and color

Working with all kinds of polymers & reinforced polymers, colors, and finishing.

We manufacture sustainable and eco-friendly plastic parts

If you have a product idea or design and are searching for a company to partner with and guide you through your search for sustainable solutions, you’re looking in the right place.

We are a company that values sustainability, and we take action on finding sustainable solutions for our clients and our operations.

Testimonials

The service is great – they are very knowledgeable, comes up with solutions and delivers what they promise.Francis Vargas, SPLIN

For our technical parts, we count on IPIC for their expertise in the industry and their constant drive for quality in what they make. Head of Industrialization, SECURITY Sector

As a young start-up, we needed expertise to bring our product to life, IPIC Plastic has been a great partner in advising us and producing our piece.CEO, B-WAT

News

Upcoming solar installation

In its quest toward a more sustainable future, IPIC PLASTIC started the process to find a partner for its upcoming solar installation. The goal is to have >150 Pannels placed in the coming year and help to reduce our carbon footprint even further.

Member Board of Plastiwin

We are proud that on 11th April 2023, our director, Antoine Carlhian, has been appointed as Board Member of Plastiwin.

Company Discovery Day

In October 2022, IPIC PLASTIC participated for the first time to the JDE (Journée Découverte Entreprise). This event ended being a great success as we welcomed over 400 attendees from all ages in 1 single day

Articles

The Benefits of Plastic Pieces Over Metal Parts

In the world of manufacturing, there are many decisions to be made. One of the most important decisions is…

How to be sustainable in Plastic Injection Molding

Plastic injection molding is a process of manufacturing plastic parts by injecting molten plastic into a mold…

Supporting the Local Economy with Plastic Injection Molding

When it comes to plastic injection molding, engineers and business owners alike are often concerned with…

Contact form

Please leave your contact details & we will be in touch shortly.

We would love to hear from you!

General office

Rue Haut-Vinave 63,

4682 Oupeye, Belgium

+(32) 4 286 48 85

Opening hours

| Monday | 7:30 - 16:00 |

| Tuesday | 7:30 - 16:00 |

| Wednesday | 7:30 - 16:00 |

| Thursday | 7:30 - 16:00 |

| Friday | 7:30 – 13:00 |